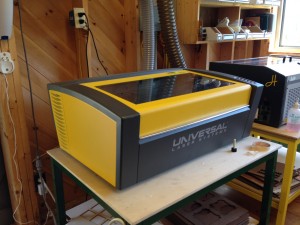

More than a month ago, I returned from the open studio residency at Haystack in Maine; two weeks of uninterrupted time in three studios: graphics, wood and a digital fabrications facility. I came home renewed and excited about prospects for new work. I went to continue further explorations with 'cutting' using new tools in the fab lab. Haystack established it in 2011 and was the result of a collaboration with MIT. It includes a CNC router, laser cutter, 3D printer, milling machines, sign center and computer terminals, and was staffed by two tech assistants from MIT. I spent much time there experimenting primarily with the laser cutter.

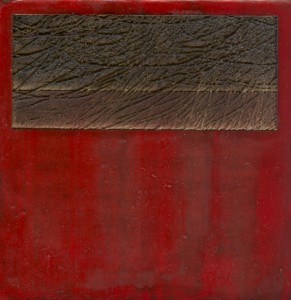

There are two different cutting techniques one can employ with the laser cutter: vector and raster. Vector is more adept at cutting shapes out or into a material; raster tends to be used for engraving and making relief cuts. I tried both and found that I preferred the raster images. Some experimenting below:

My goal was to make work that looked like it was not done with a machine. Image selection and treatment of materials contributed to the look. More examples below:

I also spent some time in the wood working studio. While there I observed one of the participants working with stacks of wood and realized that I could use a similar approach with book covers. Her primary tool was a scroll saw. I came home and purchased one!

Other highlights: